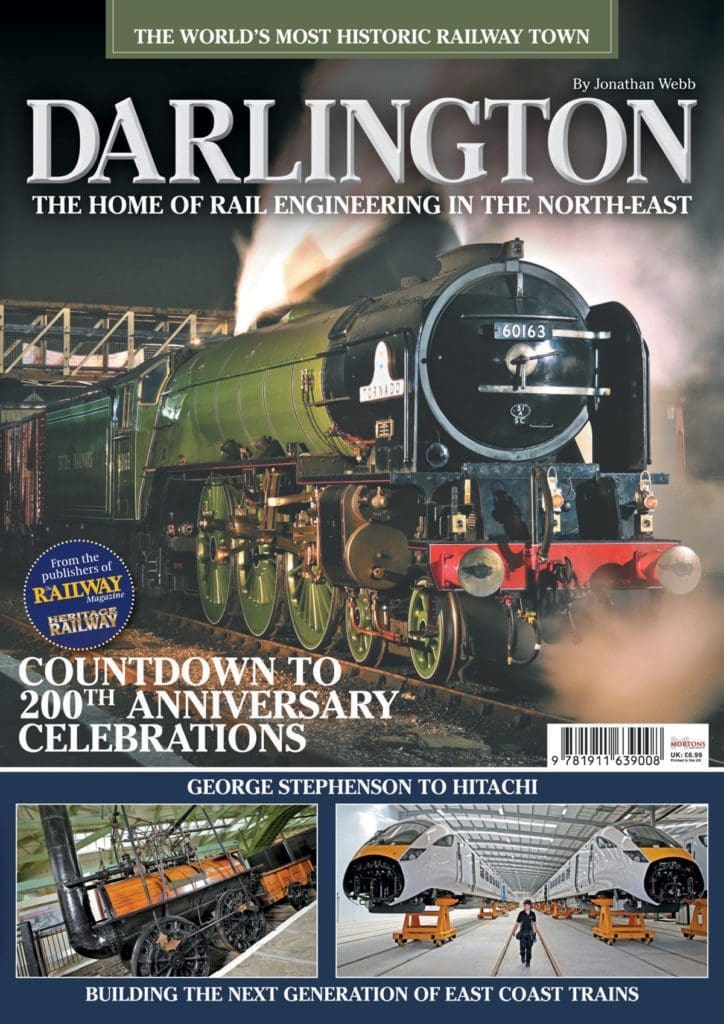

Peppercorn A1 Pacific No. 60163 Tornado has helped revive the legacy of loco building in Darlington.

Originally designed by Arthur H Peppercorn, the last chief of the London & North Eastern Railway (LNER), the A1s were the last in a line of famous express passenger steam locomotives set for the East Coast Main Line (LNER).

Written by Jonathan Webb, Darlington tells the story of how Tornado helped put Darlington’s legacy back on the map. Here are five things you may not have known about the revolutionary locomotive.

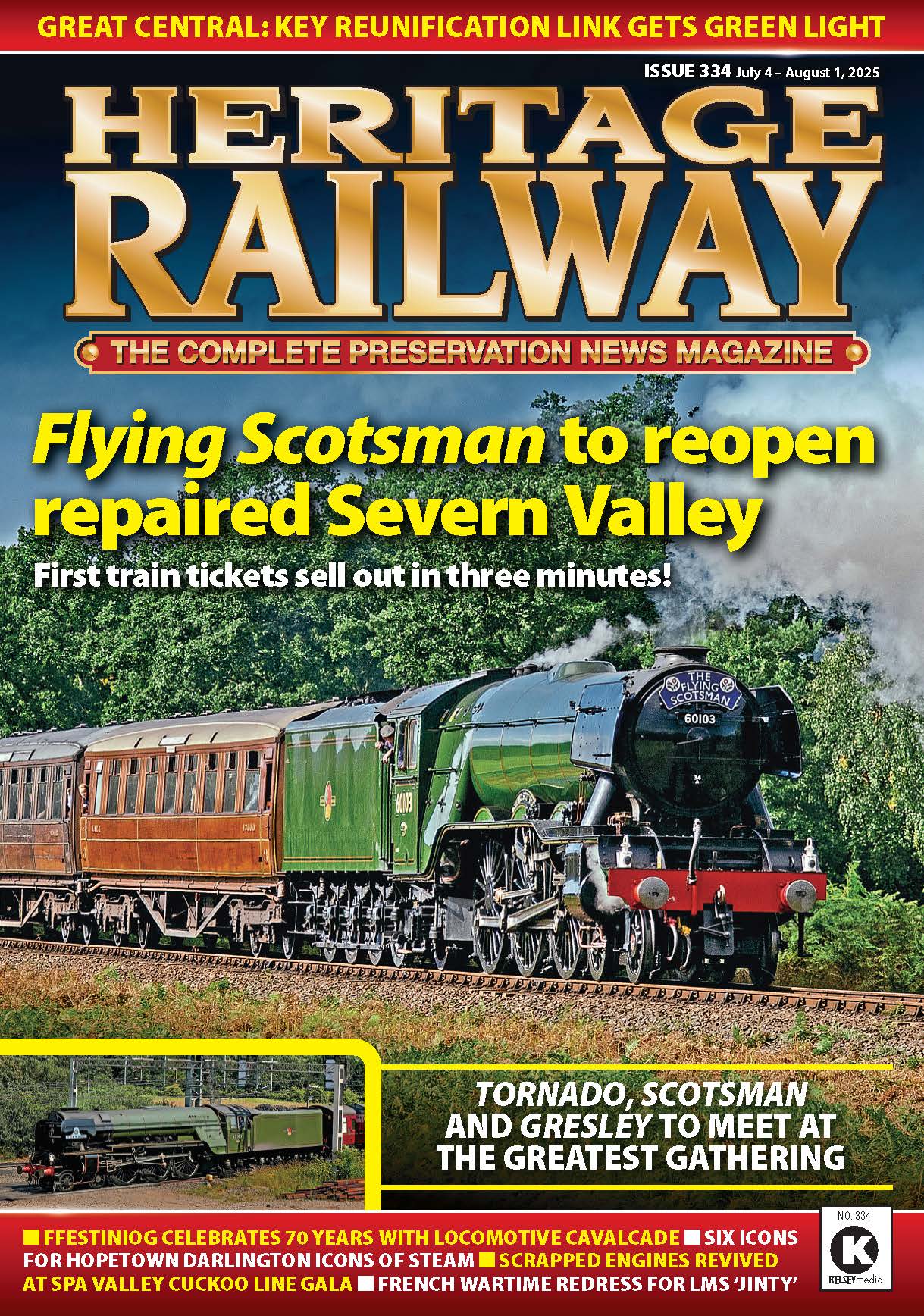

Enjoy more Heritage Railway reading in the four-weekly magazine.

Click here to subscribe & save.

1. The original 49 Peppercorn Class A1s were ordered by the LNER after the nationalisation of the railways

As designed, they were ideally suited for the postwar world of poor maintenance and heavy trains, with their 50sq ft grate allowing them to use lower grade coal than their predecessors. The final five were even equipped with roller bearings enabling them to go for an average of 118,000 miles between heavy repairs, making the A1s the cheapest to run of all British steam locomotives in the same category.

2. Why number 60163?

There was a formal launch on November 17, 1990 which was attended by 80 people. The trust announced that the locomotive would carry the number 60163, following on from BR 61062 Saint Johnstown, but the name Tornado had not been chosen at this early stage. A pledge of £50,000 sponsorship from New Cavendish saw owner Allan Levy select the name Tornado for 60163, as tribute to the RAF crews that were engaged in the Gulf war that was being fought at the time.

3. Was the 60163 Tornado meant to be oil-fired?

Yes, originally, Tornado was planned to be powered by oil, but this proposal was dropped on economic grounds, and instead, the trust opted for conventional coal firing. The locomotive is able to carry 7.5 tons of coal and has a water capacity of 6200 gallons, with coal capacity being sacrificed in favour of water. The tendor also utilises the pick-up space and has additional volume added around the top filter. The A1 is also fitted with a sophisticated electrical system.

4. By 1992, the trust had carried out detailed examinations on almost 400 documents held at the National Railway Museum

The A1 Steam Locomotive Trust needed to determine what aspects of the original design had to be modified and updated to align with the modern rail standards. The trust had also produced a computerised catalogue of a further 300 drawings, cross-referenced from those already examined.

The trust put a proposal forward to the National Railway Museum to digitally scan the original drawings to provide a compact and convenient means of storage and reproduction. This move would also allow the trust to convert the scanned drawings into vector form or modification using a computer aided design (CAD) system.

5. A momentous day

April 22 proved to be a momentous day for the trust, when the frame plates were rolled by British Steel at its Scunthorpe Works. The trust had long held the ambition to have 60163’s frames cut at Doncaster Works, using the same machine that had profiled the frames for the A1s and A4s, but alas, this machine was sold just days before Tornado’s frames were due to arrive. Instead the new locomotive’s main frames were profiled at BSD Plate and Profile Product’s 38-acre site in Leeds.

Mrs Dorothy Mather, the widow of the locomotive’s 1940s designer, Arthur H Peppercorn, had the honour of started the CNC Plasma and Oxy fuel profile cutting system which cut the main frames from steel donated by British Steel. The profiling of the main frames involved cutting 25mm and 30mm plate with consistent high quality finish.

This is a short feature, taken from the bookazine, Darlington, a special publication from Mortons Media Group which examines the important role played by the town in the invention of railways and how, two centuries on, the nearby Hitachi factory ensures the North East is still at the heart of rail engineering technology.

Also on the Peppercorn A1 Pacific No. 60163 Tornado

Order your copy of the 116-page bookazine Darlington: The Home of Rail Engineering in the North-East for just £6.99.

Advert

Enjoy more Heritage Railway reading in the four-weekly magazine. Click here to subscribe.

Enjoy more Heritage Railway reading in the four-weekly magazine. Click here to subscribe.